Turfstone offers specific and distinct advantages for controlling erosion and stabilizing slopes, embankments, river and low flow channels, flood plains and the shorelines of inland rivers, dikes, creeks, lakes, ponds and reservoirs, where there is no extreme wave action.

Turfstone can also be used to reinforce grassy areas subjected to wheeled traffic that would otherwise become so compacted as to inhibit the permeability of the soil that is necessary for the grass to survive. The Turfstone paving system is an ideal overflow parking facility for parks, historical sites, institutions, university and school campuses and golf courses. Because Turfstone enables the traffic to go where the grass grows, it is a suitable for emergency or maintenance vehicle access which must remain greenspace.

Compared to asphalt, grassed grid pavements can reduce surface air temperatures by 2° to 4° F (1° to 2° C) and radiometric temperatures by 4° to 6° F (2° to 4° C).

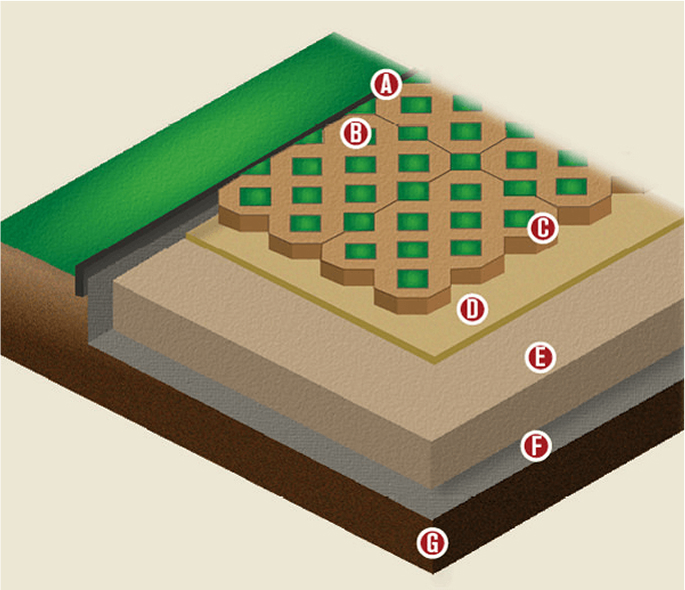

Diagram Key

-

A

Edge restraint - may be wood, metal, plastic, or concrete

-

B

Soil mix with seed or sod plugs

-

C

Turfstone - concrete grid

-

D

Bedding sand - graded sand meets ASTM C 33 Moist Washed Concrete Sand

-

E

Base layer - graded rock class II or 3/4 minus mix compacted

-

F

Geotextile - filter fabric as needed per site conditions

-

G

Compacted native soils

Frequently Asked Questions

Is the base material important?

Yes. The base material absorbs the loads applied to the surface of the pavers. Without the compacted base the pavers could fail by rutting or sinking.

What type of material is used for the base?

The proper material is a crushed angular gravel mix typically referred to as a 'crushed miscellaneous' or '3/4 minus'.

What is the geotextile and is it necessary?

Geotextile is a heavy fabric that functions similar to a coffee filter. As water goes in and through the base it prevents the base from migrating into the existing soils. It may be necessary in areas with high water tables.

Is the bedding sand used for leveling the pavers?

No. The bedding sand should be loosely and evenly screeded at a depth of 1 to 1 1/2 inches. It fills the joints from the bottom up and allows for removal of minor height differences between pavers during the first compaction. It should not be used to fill depressions in the base material.

Is the joint sand different than the bedding sand?

Not always. Bedding sand can be used to fill the joints but may be difficult to sweep/vibrate into the joint. Dry bagged joint sands are typically finer, and sweep/vibrate easily into the joints assuring good interlock.

Are there dye lots with pavers?

Yes. Although typically not referred to as dye lots, pavers are made of natural materials which may cause minor color variations between pallets or batches. The contractor should lay the pavers from various pallets simultaneously to assure a good color mix.

Is the edge restraint important?

Yes. Without the edge restraint the pavers will not remain interlocked and could fail. There are many different types of edge restraints commonly used such as wood, metal, plastic, or concrete.

Do I need to seal the pavers?

No. Sealers, however, may offer benefits including color enhancement, joint sand stabilizing, and stain resistance. Areas such as pool decks and back patios are commonly sealed.

How long will interlocking concrete pavers last?

Typical residential installations will last 30 years or more, with little or no maintenance.